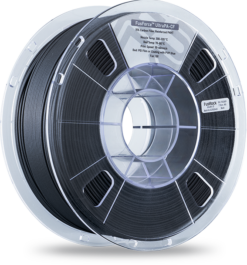

FusRock ASA 1.75mm 1kg

$29.95

* Get free shipping for orders over $150.00

FusRock ASA Filament 1.75mm 1kg, UV resistance, weather resistant best for outdoor usage.

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $26.96 |

FusRock FusFun ASA Filament

FusFun™️ ASA Filament has excellent all-round properties, featuring minimal odor and UV resistance. It is an alternative to ABS filaments due to its similar physical and mechanical properties with ABS. FusFunTM ASA is not sensitive to moisture. Once the sealed packaging is open, there is no need for moisture-proof measures. FusFreeTM S-Multi Quick-Remove Support Material is a good support material for FusFunTM ASA, and it solves the question of poor support surface quality when FusFunTM ASA works as a self-support material.

Material Properties

| PropertyTesting methodTypical value | ||

| Density | ISO 1183 | 1.1 g/cm3 |

| Glass transition temperature | ISO 11357 | 98°C |

| Vicat softening temperature | ISO 306 | 105°C |

| Melt index | 220℃,2.16kg | 5.6 g/10min |

| Determination of temperature | ISO 75: Method A | 90°C(1.8MPa) |

| Determination of temperature | ISO 75: Method B | 96°C (0.45MPa) |

| Tensile strength(X-Y) | ISO 527 | 38.5±1.6MPa |

| Yield elongation(X-Y) | ISO 527 | 2.38±0.23% |

| Young’s modulus(X-Y) | ISO 527 | 2317±246MPa |

| Tensile breaking strength(X-Y) | ISO 527 | 32.23±1.13MPa |

| Elongation at break (X-Y) | ISO 527 | 5.2±1.4% |

| Tensile breaking strength (Z) | ISO 527 | 27.87±0.4MPa |

| Elongation at break (Z) | ISO 527 | 2.43±0.27% |

| Young’s modulus (Z) | ISO 527 | 2037±64MPa |

| Elongation at break (Z) | ISO 527 | 1.55 ± 0.12 % |

| Bending strength (X-Y) | ISO 178 | 64.49±1.3MPa |

| Bending Modulus (X-Y) | ISO 178 | 2399±147MPa |

| Charpy impact strength (X-Y) | ISO 179 | 12.9±0.9KJ/m2 |

Specimens printed under the following conditions: Nozzle size 0.4mm, Nozzle temp 250°C, Bed temp 105°C, Print speed 50mm/s, Infill 100%, Infill angle ±45°.

Recommended printing conditions

| Nozzle Temperature240-260°C | |

| Recommended Nozzle Diameter | ≥0.2mm 0.7/cm |

| Recommended build surface treatment | Glass、PEI Film or PC Film 87C |

| Build plate temperature | 90-110°C 198 |

| Raft separation distance | 0.18-0.2mm |

| Cooling fan speed | Off |

| Print speed | 20-90 mm/s |

| Retraction distance | 2-5 mm |

| Retraction speed | 1800-3600 mm/min |

Printing Tips: 1. Compared with PLA and PETG filaments, ASA/ABS needs a higher environment temperature to release the residual stress during printing. Please keep the chamber closed to avoid warping and layer separation issues during the process. If your printer has a heated enclosure already, please keep the chamber temperature between 60-80°C. 2. If you find the printing quality decreases after ASA has been exposed in the air for a long time, please dry the filament at 70-80°C for 4-6h.

asa 3d printing filament

printing with asa filament

asa filament properties

asa filament settings

asa filament density

| Weight | 1.4 kg |

|---|---|

| Dimensions | 24 × 24 × 8 cm |

| Color | Green, Orange, Nature, Brown, Black, Red, Blue, Grey, Skin/Beige, Yellow |

Please sign in

Related products

Filaments

Filaments

Filaments

Filaments

Filaments

Filaments

Filaments