FusRock

FusRock FusFun ASA Aero 1KG

Pickup available at Regents Park

Usually ready in 1 hour

Shipping & Returns

Row content

FusRock FusFun ASA Aero

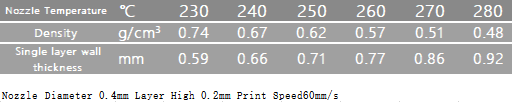

FusFun™ ASA-Aero is a type of light weight 3D printing material specially developed for aircraft model, ship model, drone and other fields. It can be controlled the foaming ratio by adjusting the temperature during the printing process, so that the density of the material extruded by the nozzle can be adjusted within a certain range. With this technique, it is easy to reduce the weight of the prints. In the best-case scenario, the prints weight can be reduced to 50% of a prints in ordinary ASA. In addition to that, the matte texture of the prints’ surface can reduce the visibility of printed layers and thus gives a smooth surface finish.