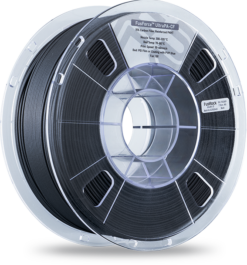

FusRock TPU 95A HF (support upto 100mm/s) 1KG

$39.95

* Get free shipping for orders over $150.00

FusRock TPU 95A HF (support upto 100mm/s)

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $35.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $35.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $35.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $35.96 |

FusRock TPU 95A HF Filament

FusFlexTM TPU95A-HF is TPU material that is easy to print. FusFlexTM TPU95A-HF is easier to

be extruded than other conventional TPU consumables under the same hardness. When a

suitable extruder is selected, FusFlexTM TPU95A-HF can support a printing speed of more than

100mm/s.

Material Properties

| PropertyTesting methodTypical value | |||

| Density | ISO 1183 | 1.15g/cm³ | |

| Hardness | ISO 7619 | 95A | |

| Melt index | 200°C, 2.16kg | 30g/10min | |

| Vicat softening temperature | ISO 306 | 99°C | |

| Tensile strength(X-Y) | ISO 527 | 31.81±3.26MPa | |

| Elongation at break (X-Y) | ISO 527 | 471±81% | ISO 178 |

| Tensile Stress at 100% (X-Y) | ISO 527 | 9.75±0.16MPa | |

| Tensile Stress at 200% (X-Y) | ISO 527 | 12.2±0.27MPa | |

| Tensile Stress at 300% (X-Y) | ISO 527 | 17.0±0.49MPa |

Specimens printed under the following conditions: Nozzle size 0.4mm, Nozzle temp 210°C, Bed temp 50°C, Print speed 60mm/s, Infill 100%, Infill

angle ±45°.

Recommended printing conditions

| Nozzle Temperature205-225°C | |

| Recommended Nozzle Diameter | ≥0.2mm |

| Recommended build surface treatment | Glass, PEI Film or PC Film |

| Build plate temperature | 20-50°C |

| Raft separation distance | 0.18-0.22mm |

| Cooling fan speed | On |

| Print speed | 30-100 mm/s |

| Retraction distance | 1-5 mm |

| Retraction speed | 1800-3600 mm/min |

Printing Tips: 1. If you want to achieve high-speed printing, it is recommended to use direct extruders, such as BMG extruder, Titan extruder and Hemera extruder, and appropriately increase the nozzle temperature. 2. TPU material is very easy to absorb moisture when exposed to air, and printing after absorbing moisture will result ozzing, extruding with bubbles and rough surface appearance, thus reducing print quality. It is recommended that put the filament into a dry box (humidity below15%) immediately after opening the FusFlex™ TPU95A-HF vacuum foil bag for printing. Please put the unused filament back into the original aluminum foil bag for sealed storage. 3. After the material is damp, there will be more printing ozzing, bubbles extruded and rough printing surface. Please dry the filament in an oven at 70-80 for 4-6h to restore the printing quality of FusFlex™ TPU95A-HF.

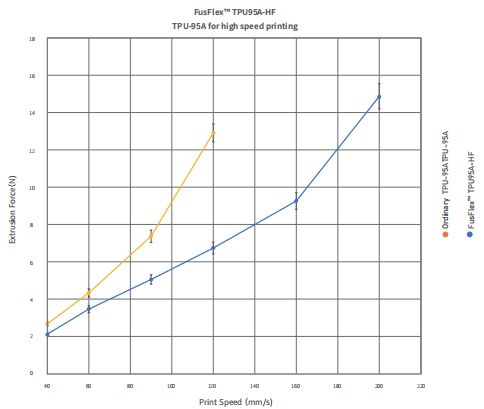

Extrusion Force vs Print Speed Test

Test parameters:

temp 220°C, 12mm length brass heat block, BMG extruder, Phaetus plated copper nozzle, Nozzle size 0.4mm,

Layer Height 0.2mm.

| Weight | 1.4 kg |

|---|---|

| Dimensions | 24 × 24 × 8 cm |

| Color | Transparent, White, Black |

Please sign in

Related products

Filaments

Filaments

Filaments

Filaments

Filaments

Filaments