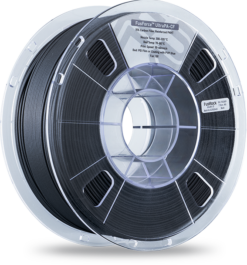

FusRock Odorless ABS 1KG

$24.95

* Get free shipping for orders over $150.00

FusRock Odorless ABS Filament, High Quality 3D Printer ABS Filament, high temperature resistance.

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $22.46 |

FusRock Odorless ABS

FusRock FusFun™ ABS is a high-strength ABS-based 3D printing filament with outstanding mechanical properties. The tensile strength of its 3D printed parts in the XY axis direction can be close to 40MPa. Therefore, FusFunTM ABS is ideal for printing functional prototypes, jigs and low- volume production parts.

The main raw material of FusFunTM ABS is an ABS resin synthesized by continuous bulk polymerization technique. Thanks to this advanced production process, the residual amount of solvents and monomers used in the production process in the final ABS product is so low that the filament has a low odor during printing.

FusFunTM ABS can be used together with FusFreeTM S-Multi Quick-Remove Support Material to solve the poor surface of complex model above supports.

Material Properties

| PropertyTesting methodTypical value | ||

| Density | ISO 1183 | 1.05g/cm3 |

| Glass transition temperature | ISO 11357 | 101℃ |

| Melt index | 250℃,2.16kg | 7.8g/10min |

| Vicat softening temperature | ISO 306 | 103°C |

| Determination of temperature | ISO 75: Method A | 86°C (1.8MPa) |

| Determination of temperature | ISO 75: Method B | 92°C (0.45MPa) |

| Tensile strength(X-Y) | ISO 527 | 38.96±0.33MPa |

| Elongation at Yield(X-Y) | ISO 527 | 2.32±0.02% |

| Young’s Modulus(X-Y) | ISO 527 | 2384.22±20.00MPa |

| Tensile breaking strength(X-Y) | ISO 527 | 33.36±0.53MPa |

| Elongation at break(X-Y) | ISO 527 | 5.77±0.84% |

| Tensile breaking strength (Z) | ISO 527 | 26.16±1.73MPa |

| Elongation at break (Z) | ISO 527 | 1.62±0.14% |

| Young’s modulus (Z) | ISO 527 | 1967.57±119.93MPa |

| Tensile breaking strength (Z) | ISO 527 | 32.25±0.72MPa |

| Young’s Modulus (Z) | ISO 178 | 2201.74±74.91MPa |

| Elongation at break (Z) | ISO 527 | 2.70±0.59% |

| Bending strength (X-Y) | ISO 178 | 67.81±0.54MPa |

| Bending Modulus (X-Y) | ISO 178 | 2400±79.69MPa |

| Charpy impact strength (X-Y) | ISO 179 | 20.03±1.32KJ/m² |

Specimens printed under the following conditions: Nozzle size 0.4mm,Nozzle temp 250°C, Bed temp 75°C, Print speed 40mm/s, Infill 100%, Infill angle ±45°

Recommended printing conditions

| Nozzle Temperature240-260°C | |

| Recommended Nozzle Diameter | ≥0.2 mm |

| Recommended build surface treatment | Glass、PEI Film or Coating with PVP glue |

| Build plate temperature | 100-110 °C |

| Raft separation distance | 0.2-0.22mm |

| Cooling fan speed | Off |

| Print speed | 30-90 mm/s |

| Retraction distance | 1-5 mm |

| Retraction speed | 1800-3600 mm/min |

| Recommended Support Material | FusFreeTM S-Multi Quick-Remove Support |

Printing Tips: 1. Compared with PLA, PETG and other materials, ABS materials need a higher chamber temperature to help release the residual stress during the printing process. Please keep the printer chamber closed during the printing process. It can effectively avoid printed parts from warping and cracking. If the device has a heated chamber, it is recommended to set the temperature of heated chamber between 60-80°C. 2. If the ABS filament has been unpacked for a long time and the printing quality starts to degrade during the printing process, please dry the filament at 70-80°C for 4-6 hours before printing. 3. Although FusFunTM ABS has much less odor compared with similar products, it is still recommended to place the printer in a well-ventilated area during printing.

| Weight | 1.4 kg |

|---|---|

| Dimensions | 24 × 24 × 8 cm |

| Color | Green, Orange, Brown, Black, Army Green, Red, Blue, Grey, Silver, Purple, Light Orange, Skin/Beige, Yellow |

Please sign in

Related products

Filaments

Filaments

Filaments

Filaments

Filaments

Filaments