FusRock PLA Aero Filament 1KG

$59.95

* Get free shipping for orders over $150.00

FusRock PLA Aero Filament, reduced to 50% of a model printed with ordinary PLA.

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $53.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $53.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $53.96 |

Discount per Quantity

| Quantity | Discount | Price |

|---|---|---|

| 10 + | 10% | $53.96 |

FusRock PLA Aero Filament

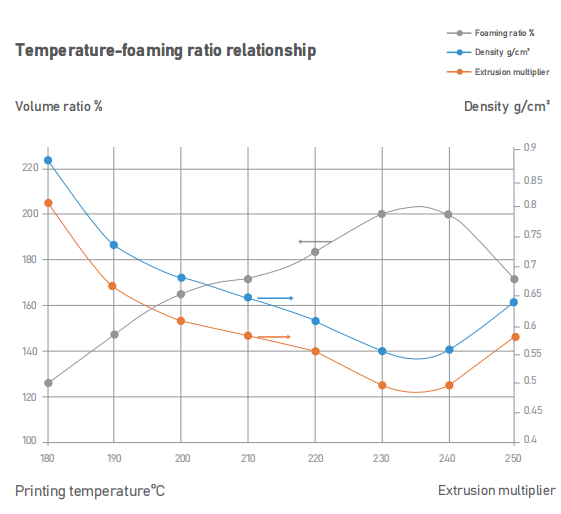

FusFun™ PLA-Aero is a type of lightweight 3D printing material specially developed for aircraft

model, ship model, drone and other fields. PLA-Aero controls the foaming ratio of the material

by adjusting the temperature during the printing process so that the density of the material

extruded by the nozzle can be adjusted within a certain range. With this technique, it is easy to

reduce the weight of the model. In the best-case scenario, the model weight can be reduced to

50% of a model printed with ordinary PLA. In addition to that, the matte texture of the printed

surface can reduce the visibility of printed layers and thus give a smooth surface finish.

Filament Physical Properties

| PropertyTesting methodTypical value | ||

| Density | ISO 1183 | 1.1 g/cm³ |

| Glass transition temperature | ISO 11357 | 60 °C |

| Melt index | 200 °C, 2.16 kg | 10 g/10min |

| Vicat softening temperature | ISO 306 | 65 °C |

Specimens printed under the following conditions: Nozzle size 0.4mm,Nozzle temp 250°C, Bed temp 75°C, Print speed 40mm/s, Infill 100%, Infill angle ±45°

Recommended printing conditions

| Nozzle Temperature180-250 °C | |

| Optimum foaming temperature | 230 °C |

| Recommended Nozzle Diameter | ≥0.4 mm |

| Recommended build surface treatment | Glass/PEI Film/PC Film or plate applied with PVP glue |

| Build plate temperature | 50 °C |

| Raft separation distance | 0.2 mm |

| Cooling fan speed | ON |

| Print speed | 30-90 mm/s |

| Retraction distance | Closed |

| Retraction speed | Closed |

Printing Tips:

- Since PLA-Aero adopts the “On-Demand foaming” technology, the filament will continue to expand in the nozzle after being heated during the printing process. Therefore, it will cause unavoidable stringing during the nozzle movement. Even adjusting the retraction setting in the slicing software cannot solve this problem. Based on the above, it is recommended to turn off the retraction setting. The string on the surface of models can easily be removed by hand.

| Weight | 1.4 kg |

|---|---|

| Dimensions | 24 × 24 × 8 cm |

| Color | White, Grey, Yellow |

Please sign in

Related products

Filaments

Filaments

Filaments

Filaments

Filaments

Filaments

Filaments